Automation of machines and plant systems can ensure more effective quality control by checking for any abnormal reactions during machine operation.

This allows us to collectively manage all the necessary information about monitoring and controlling processes and machines, tracking and controlling quality information, performance statistics, warehousing, inventory. warehouse, application of materials, personnel, production machinery, etc. by collecting the production status of existing 4Ms (people, methods, materials and machines) in real time by means of information system.

Woosung Ind Co., Ltd.’s Smart Factory Monitoring.

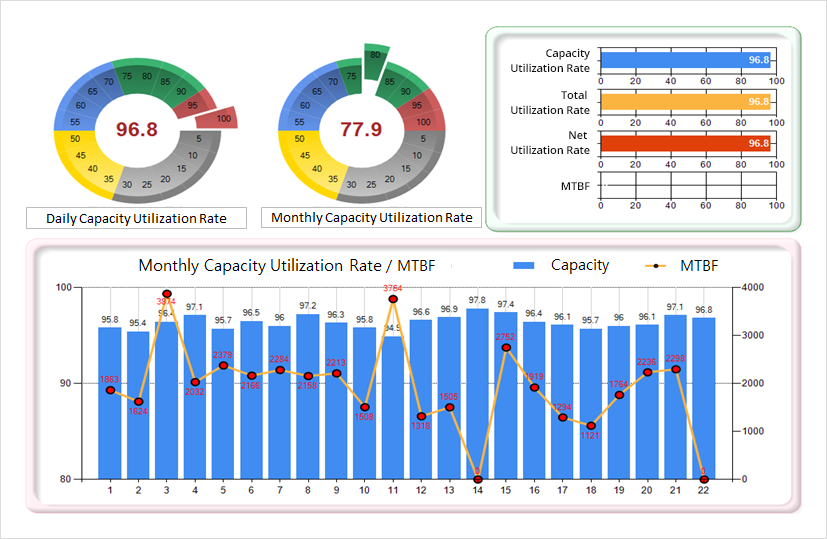

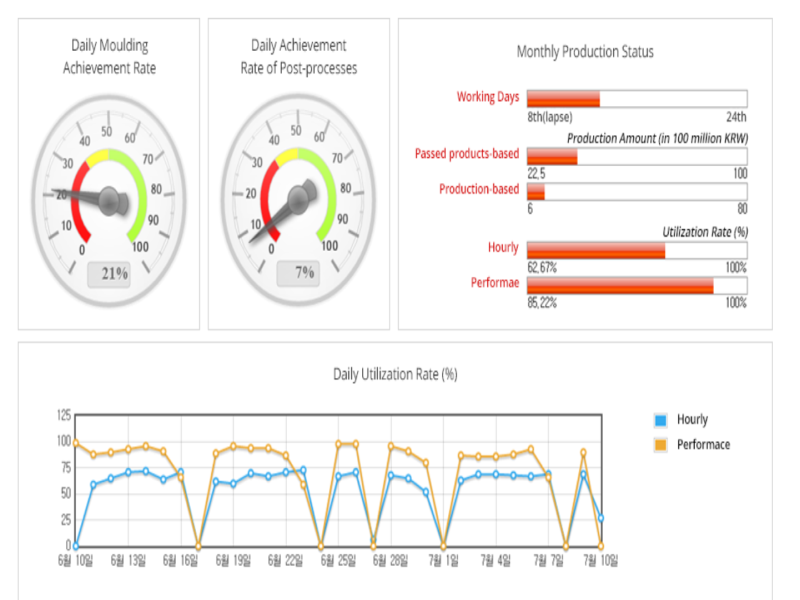

Production index system

As an activity that reduces any non-value-added activities, it increases the efficiency of plant management processes by allowing us to react to current normal situations. such as unplanned downtime, failures, or bottlenecks.

Woosung Ind Co., Ltd.’s Smart Factory Monitoring.

Control System CMB

Any possible cause of failure can be eliminated by monitoring logistics information and environmental factors in real time from material warehousing, weighing and mixing to casting.

Its precise real-time data allows us to precisely guide plant operations, respond to any unusual situations and report them.

System Smart Factory Monitoring of Woosung Ind Co., Ltd.